Material (commonly used)

· carbon steel:45#、20#、1020.

· Alloy steel:4140/4145、4330V、4340

· Alloy tool steel:D2、S7、H13

· Austenitic stainless steel:316L、304、17-4PH、2205、UNS31803

· Martensitic stainless steel:410、420

· High temperature alloy steel:Inconel718、625、725、925

· Non-magnetic steel:P550

· Titanium alloy:TC4、TC11、TA6

· Copper, aluminum

Seed has a professional procurement team and a huge supplier network, which can purchase different types of steel and imported steel in the market according to customer requirements.

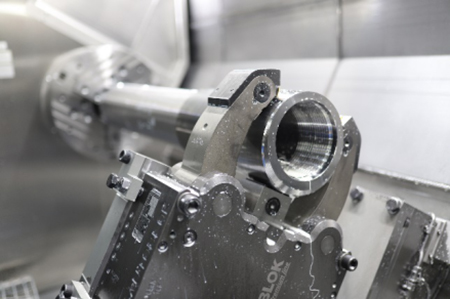

Product Features (Deep hole, Eccentric)

· We have obtained the API Q1-3702 qualification certificate, as well as the patent thread processing qualification of several customers. We have rich experience in thread processing, and hardware & software facilities.

· We specialize in processing high-precision shaft parts with length within 3 meters (please consult us if the part length exceeds this range)

· The draw ratio of deep blind hole machining reaches 40 times

· It is suitable for processing various high-precision, special materials, eccentric holes, elbows, special-shaped and complex geometric parts.

Machining Equipment

· We have more than 300 sets of advanced R&D and production equipment, such as turning-milling composite machining center, five-axis machining center, four-axis vertical machining center, CNC horizontal boring and milling machine, Taiwan all-round CNC lathe, deep hole drilling, boring and honing machines, etc.;

· Complicated structural parts of long shaft casing with diameter ≤400mm and length ≤3000mm

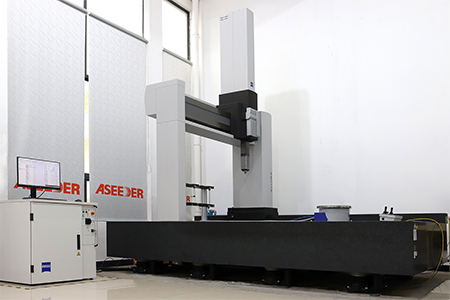

Inspection capability

· Professional inspection team

· High-end Inspection equipment

· Complete inspection process