Technical Support Case Study

Case 1

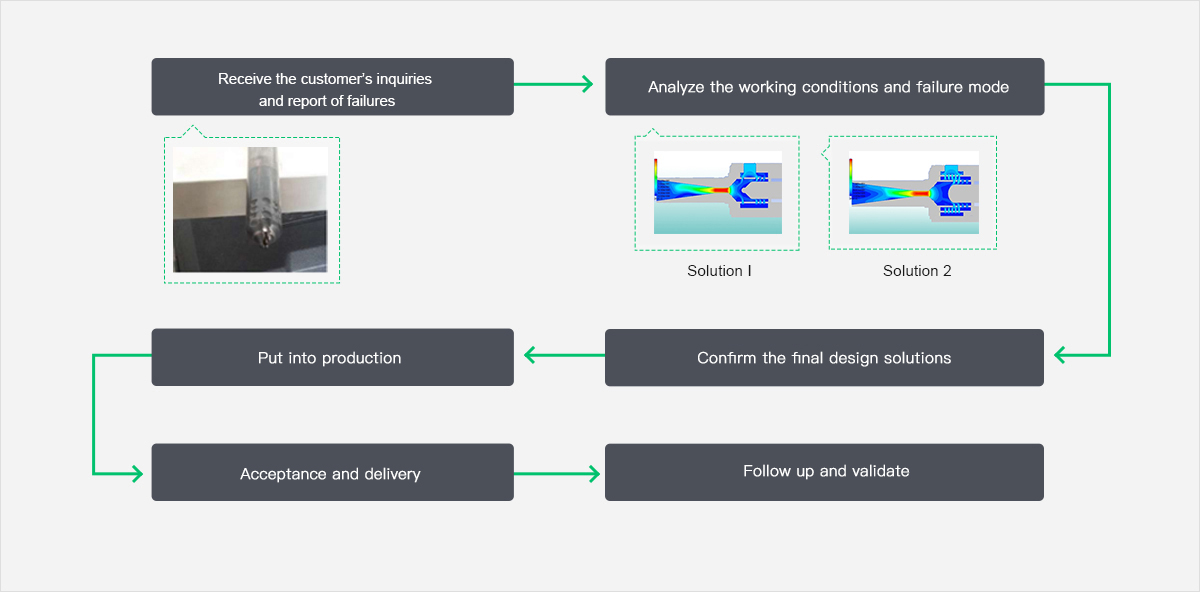

Receive the customer’s inquiries and report of failures → analyze the working conditions and failure mode → apply design optimization solutions → confirm the final design solutions → put into production → acceptance and delivery → follow up and validate

The

valve is designed for applications at a pressure of 22.45mpa, max temperature

of 510℃, a maximum closing pressure difference of 22.45Mpa, an inlet

pressure of 20.52Mpa and an outlet pressure of 0.86Mpa in operation, a working

temperature of 410℃, and an average flow rate of

8000kg/h under normal conditions (half switching time, so the flow rate is

16000kg/h on opening).

The

medium that flows through the valve is LPH high resolution oil residue, with a

density of 1200kg/㎥, a dynamic viscosity of 50mPa·s, a solid content

of 53.6%, and a gasification capacity of 1.5% ~ 10%. The valve core is eroded

by the fluid medium containing solid particles, which leads to valve failure.

According to Preston's grinding empirical formula, the erosion of the valve

plug is proportional to the velocity and pressure of the fluid around the plug.

Case 2

The demand for petroleum is increasing year after

year, and the reserves of petroleum exploitation are decreasing year after

year. The development of coal-to-oil technology has effectively alleviated this

energy problem. However, the harsh environment faced by coal-to-oil makes its

requirements for materials and equipment very high. As a key core component of

coal-to-oil technology, the demand for one-way valves is growing rapidly, but

the R&D and production of one-way valves was monopolized by Germany in the

early years, the unit price is very high, and the service life is only 1 to 3

hours, all of these were seriously restricting the development of coal

technology.

In order to meet the large demand for

one-way valves from customers in the coal-to-oil field, Seed concentrated on

researching the production technology of one-way valves and evaluated the

independent production of key parts and components of coal-to-oil equipment.

The achievement breaks the monopoly of overseas production and our technology

made a major contribution.

Autonomous production of one-way valves

realizes the reduction of the price to 1/9 of the original, saving costs, and

greatly improving the service life. It was reported by CCTV News Network

"Ingenuity and innovation, showing a new business card of made in

China."

Responsibilities:

1.Responsible for the developing new suppliers, optimize and integrate existing suppliers, and establish supplier management library.

2.Responsible for organizing engineering and quality personnel to perform on site audits and submit supplier admittance report.

3.Claim

and negotiate the non-conforming items of the products produced by the supplier.

5.Responsible for the material transfer and inspection of Import and marketing varieties and products in the workshop, and follow up the outsourcing order cycle.

Job Requirements:

Bachelor

degree or above, major in mechanical or related, two years or above experience

in outsourcing / purchasing in machining industry

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

3.Having the work experience in large enterprises is preferred.

4.Be excellent at communication and expression, clear logical thinking, good work literacy.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

1. Complete the design and development tasks of corresponding modules according to the development plan.

3. Responsible for the development and maintenance of IT management system.

Job Requirements:

1. Bachelor degree or above, more than 2 years of application development experience, at least participated in module design and code

development of more than one large software project;

2. Have Java language or C language platform development programming experience.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

5.Complete other tasks assigned by management.

5. Have a strong sense of responsibility and confidentiality, being of strong principles.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

1.Proficient in machining equipment such as turning, milling, planing, grinding, etc., able to deal with quality problems on site, and repair plans for substandard products;

2.Be able to independently complete machining process and analysis, be able to do technical review and technical scheme, including tool selection, equipment selection, processing technology scheme, product difficulty, risk point identification and evaluation, etc

3. Responsible for on-site product technology innovation and process optimization to improve product qualification rate and production efficiency;

4.Familiar with mechanical processing of various material properties, such as alloy steel, stainless steel, high temperature alloy steel, can master its cutting performance and processing deformation;

5. Familiar with the inspection equipment, such as CMM, profilometer, etc., can ensure that the various geometric tolerance requirements of drawings meet the requirements

7. Have experience in the production of shaft type high precision parts, such as shaft length about 2000mm, accuracy within 0.02mm

(dimensional and geometric tolerance requirements);

9. Can do fixture design, inspection tool design, etc.;

1. Major in mechanical engineering;

3. 30-50 years old, more than 10 years related working experience;

4. Engineer Titile or above is preferred;

6. Strong management and interpersonal skills.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

5.Responsible for the maintenance and control of product-related quality documents and records.

4.Earnest and responsible for job, rigorous and meticulous, strong analytical and problem-solving skills; Good teamwork spirit;

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

Responsibilities:

3.Responsible for the design of hydraulic system

5.Experience in hydraulic system design is preferred.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com

4.Those who can read English drawings or use English as working language are preferred.

Tel:0731-28472167 E-mail:zhaopin@aseeder.com